The drone industry is shifting. If you look at the specs for heavy-lift platforms used in logistics, mapping, or agriculture, you will notice a pattern. The standard 6S (22.2V) setup, which served the industry well for years, is disappearing from top-tier airframes. In its place, 12S and 14S architectures are becoming the new standard.

Many operators think this is just about raw power. They assume higher voltage simply means “faster.” But that is a misconception. The move to High-voltage UAV power systems is actually about stability, efficiency, and reliability. It is an architectural decision that solves the biggest bottlenecks in modern drone design: heat and current.

When you are designing a system to carry expensive LiDAR or fly for over an hour, you cannot afford to waste energy. You need a power architecture that works with your flight controller, not against it. This article explains why the industry is upgrading to high voltage, and how this shift impacts everything from your wiring weight to your safety margins.

The Physics of Efficiency: Solving the Current Bottleneck

To understand why 6S is no longer enough, you have to look at simple physics. Power (Watts) equals Voltage (Volts) multiplied by Current (Amps). This is the rule you cannot break.

If you need to lift a heavy payload, you need more Power. If you stick with a low-voltage 6S battery, the only way to get that power is to increase the Current. But pushing high amps is a problem. It creates massive heat. The resistance in your wires and Electronic Speed Controllers (ESCs) turns precious battery energy into waste heat before it even reaches the motors.

This is where Power management optimization becomes critical. In professional drone system architectures, you must focus on maximizing the output of your high-energy density power source while minimizing losses. A low-voltage system struggles to do this because it is fighting against physics.

By switching to 12S and 14S architectures (44.4V or 51.8V), you double the voltage. This means you can cut the current in half to get the same power. Lower current means less heat. It means your system runs cooler, and more of the energy in the battery is used for flying rather than heating up the airframe.

Here is a breakdown of how the architecture changes when you upgrade:

| Feature / Metric | Standard 6S Architecture | High-Voltage 12S/14S Architecture | The Industrial Advantage |

|---|---|---|---|

| Current Draw (Amps) | Extremely High (Requires thick wiring) | Low (Reduces current by ~50%) | Less heat, higher efficiency. |

| Thermal Management | Prone to ESC/Motor overheating | Runs cool under heavy load | Extends component lifespan. |

| Wiring Weight | Heavy (Needs 8AWG or 10AWG) | Lightweight (Can use 12AWG or 14AWG) | Increases available payload capacity. |

| Voltage Sag Risk | High (Critical during takeoff) | Minimal (High voltage headroom) | Prevents false “low battery” alarms. |

| Motor Responsiveness | Sluggish near full throttle | Instant torque delivery | Better wind resistance & stability. |

Actuation Precision and Response

Your flight controller is the brain, but the motors are the muscles. In drone architecture, Actuation is the block responsible for converting commands into motor signals. It has to execute commands instantly to keep the aircraft stable.

In a 6S system carrying a heavy load, the motors are often working near their limit. If a gust of wind hits, the flight controller asks for a burst of power. But the system is already “saturated” with high amps. The response is sluggish. The drone wobbles.

With a High-voltage UAV power system, you have instant torque. The voltage provides the “pressure” needed to spin the motors up immediately. This improves Actuation efficiency. By utilizing professional solid-state battery packs, the drivers can execute commands precisely without hitting a current limit. This makes the drone feel locked-in and precise, even in windy conditions.

Enhancing System Health & Safety Margins

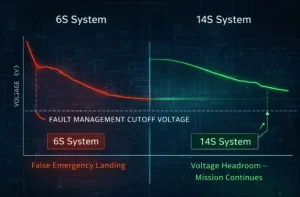

Safety is the top priority for industrial operations. This is managed by the Fault Management block, which detects failures and triggers failsafe actions. However, low-voltage systems often trigger false alarms.

Here is a common scenario: You punch the throttle to climb. The sudden demand for amps causes the voltage to drop temporarily. This is called “voltage sag.” On a 6S battery, this drop might push the voltage below the safety threshold. The Fault Management system sees this, thinks the battery is dead, and forces an emergency landing.

12S and 14S architectures solve this with “Voltage Headroom.” A 14S battery sits at over 50 Volts. Even if it sags by 2 or 3 Volts under load, it is still far above the critical cutoff point. This prevents false alarms. It gives the Prognostics system (which predicts battery status) cleaner data to work with, ensuring you only land when the battery is actually empty.

Supporting Mission-Critical Payloads

You don’t fly a drone just to fly; you fly to do a job. This involves Payload Management, which coordinates sensors, cameras, or cargo drops.

Modern payloads are power-hungry. A high-end LiDAR scanner or a thermal gimbal needs a stable power supply. In a stressed 6S system, the heavy draw from the motors can cause “noise” or fluctuations in the power line. This can glitch the Payload Controller or stop data recording.

High-voltage systems provide better power isolation. The propulsion system (motors) sips amps gently, leaving a clean, stable power capability for the payload. This ensures that your mission data is safe, regardless of how hard the drone is flying.

Case Study: Shengya 14S Solid-State System

Let’s look at a real-world application. Consider a heavy-lift VTOL (Vertical Take-Off and Landing) drone designed for corridor mapping. The engineering team initially tested it with a standard LiPo setup. The result? The wires got hot, and the flight time was stuck at 45 minutes due to thermal inefficiency.

The team decided to overhaul the power train, switching to a high-voltage configuration. They integrated a 14S solid-state unit from Shengya to handle the transition phase. The results were immediate:

- Cooler Running: The current draw dropped by 45%. The ESCs stayed cool without extra heatsinks.

- Weight Savings: They switched to thinner wires, saving 200g of cabling weight.

- Flight Time: The flight time pushed past 60 minutes, thanks to the reduced thermal loss.

By deploying this specialized 14S high-voltage solution, the team achieved the voltage stability needed to operate the VTOL transition smoothly, proving that architecture matters just as much as battery capacity.

Conclusion

The transition to high voltage is not just a trend; it is the maturation of the drone industry. We are moving away from hobby-grade limits toward professional reliability. By adopting 12S and 14S architectures, you solve the fundamental problems of heat and current that plague heavy-lift drones.

You gain better Power management optimization, more precise control, and a safer flight envelope. If you are building the next generation of industrial UAVs, do not let an outdated 6S power system hold back your performance.

The Manufacturer Behind the Technology: Shengya Electronic

Shengya Electronic works as a focused maker in the top power store field. It aims on the needs of work no-man air crafts. The company stands out by managing the entire production chain—from formulating cell materials to assembling the final battery packs. Located in a 26,000-square-meter facility, Shengya maintains a daily production capacity of 300,000 Ah.

The company’s core strength lies in developing semi-solid and solid-state lithium technologies. These products address the specific pain points of commercial flight: high energy density (up to 340Wh/kg) and long cycle life (800-1000 cycles). With ISO9001, ISO14001, and UL certifications, Shengya serves as a trusted OEM partner for clients needing reliable power solutions for mapping, surveillance, and cargo delivery.

FAQ

Q1: Can I simply upgrade my 6S drone to 12S?

A: You cannot just swap the battery. You must check if your ESCs (Electronic Speed Controllers) and motors are rated for high voltage. Putting a 12S battery on 6S electronics will likely burn them out instantly. You usually need to replace the powertrain to handle the higher voltage.

Q2: Do I need special motors for 14S batteries?

A: Yes, you generally need motors with a lower KV rating. KV represents how fast a motor spins per volt. Since you are doubling the voltage, you need a lower KV motor to keep the RPM in a safe and efficient range for your propeller size.

Q3: Is high voltage safer for heavy payloads?

A: Yes, largely because of the “headroom” we discussed. High voltage reduces the risk of current spikes causing a voltage sag that triggers a false failsafe. It keeps the drone in the air more reliably when you are carrying expensive gear like LiDAR.

Q4: How much weight can I save on wiring?

A: It can be significant on a large drone. Because you are pushing half the amps, you can often drop from heavy 8AWG wire down to lighter 12AWG or 14AWG wire. On a complex octocopter with long boom arms, this can save hundreds of grams, which goes directly back into flight time.

Q5: Why combine solid-state with high voltage?

A: It is the ultimate combination. High voltage gives you electrical efficiency (low heat), and solid-state chemistry gives you energy density (low weight). Together, they maximize the two most important factors for flight time: reducing waste and increasing fuel capacity.