The drone market is entering 2026 with a different kind of pressure than the early growth years. More platforms are moving from pilot projects to routine operations. Flight hours per airframe are rising. And for OEM teams, battery performance is no longer judged by a single “best spec,” but by how reliably the system behaves across real missions, seasons, and production batches. In that context, the most important trends for 2026 are not flashy predictions. They are practical shifts in how voltage, safety margin, and lifespan are defined, tested, and purchased.

The Drone Market in 2026: From Expansion to Operational Maturity

Industrial drone adoption is becoming less experimental and more operational. Agriculture, inspection, mapping, and certain logistics workflows are increasingly planned around repeatable routes and expected uptime. That change matters because battery stress is no longer occasional. It becomes daily. And once you scale a fleet, small inefficiencies turn into measurable cost: more battery swaps, more charging infrastructure, more downtime, and more field troubleshooting.

Drones Are Moving From Pilot Projects to Scaled Operations

In 2026, many programs will measure success in weekly flight hours and predictable completion rates, not demo performance. That pushes battery priorities toward stable voltage behavior, consistent usable energy, and safer handling routines that work for real crews. In other words, a battery that looks great in a single flight test but behaves inconsistently across months becomes a liability.

Fleet Operation Changes Battery Priorities

Fleets expose the gap between “spec sheet optimization” and lifecycle reality. One pack with slightly higher internal resistance can trigger early low-voltage warnings. A few packs in a batch can drift out of balance faster than others. Charging behavior varies between operators. Those are not edge cases. They are what scaled operations look like. Expect procurement in 2026 to ask more about consistency, validation, and support strategy than raw peak numbers.

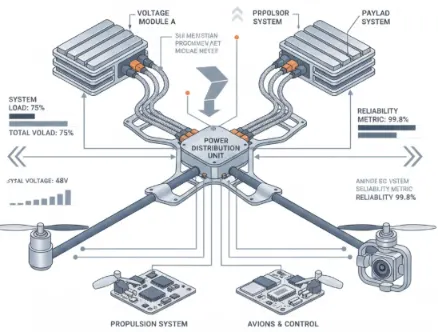

Trend 1: Voltage Architecture Will Matter More Than Capacity

A major shift for 2026 is that more OEM teams will treat voltage architecture as a system decision, not a battery choice. Capacity still matters, but it is increasingly understood as “usable energy delivered under load,” not a large Ah number printed on a label.

Why “Bigger Ah” Stops Solving Endurance Problems

Larger capacity pack does not automatically produce longer endurance if the system hits voltage thresholds early. Under heavy load, two packs with the same nominal energy can behave very differently because of voltage sag. Once voltage drops, the aircraft may land early even though energy remains. Heat also increases with higher current, and that heat accelerates degradation. This is why “bigger Ah” without a matching voltage and power strategy often fails to deliver the expected flight time in the field.

6S and 12S Will Remain Dominant in 2026

In many industrial UAV categories, 6S and 12S architectures remain dominant because the ecosystem is built around them. Motors, ESCs, chargers, and wiring standards are widely available and validated in those voltage windows. The real opportunity in 2026 is not inventing a new series count. It is choosing the right voltage architecture and validating it against the mission profile you actually fly.

If you want a deeper framework for voltage decisions, including how 6S, 7S, and 12S trade off in endurance-focused designs, this guide on 6S, 7S, and 12S battery pack selection is a useful baseline.

One side effect of this trend is that buyers will become more skeptical of simplistic claims such as “higher voltage always equals longer flight time.” Higher voltage can reduce current for the same power, which can reduce resistive loss and heat. But if the rest of the system is not engineered for that voltage window, the benefit can be small or even negative. In 2026, expect more OEM teams to ask for proof under real load rather than accept assumptions.

Trend 2: Battery Failures Will Shift From Accidents to Design Debt

In earlier years, battery incidents were often framed as “user mistakes.” In 2026, more failures will be recognized as design debt: decisions that looked reasonable early on but were never fully validated for scaling, heat, and repeated cycling.

Why “Fail Early” Is Increasing in Industrial Drones

Industrial drones often face higher duty cycles, repeated high-power takeoffs, and demanding environments that compress safety margins. When a pack is pushed near its limits, small design choices become failure accelerators: inadequate thermal paths, underestimated peak current, connector losses, and pack-to-pack inconsistency. The result is not always dramatic failure. More often, it shows up as early voltage sag, reduced usable capacity, and faster performance decline than planned.

Battery Issues Are More Often System-Level Than Cell-Level

In 2026, more teams will stop treating battery issues as “cell chemistry problems” and start treating them as system integration problems. Battery behavior is shaped by the full power chain: ESC limits, motor demand, wiring resistance, airflow and heat sinks, charging routines, and cutoff thresholds. When a platform scales, these interactions become more visible. OEM success increasingly depends on closing the gap between lab assumptions and operational realities.

Trend 3: Consistency Will Matter More Than Peak Specifications

A battery that is slightly stronger on paper is rarely the competitive advantage in 2026. Predictability is. Fleets care about repeatable behavior because planning depends on it.

Why Fleets Care About Voltage Curves, Not Just Capacity

Two packs can share the same capacity rating and still deliver different flight outcomes. The difference often comes from internal resistance, cell matching, and how the voltage curve behaves under load. In fleet operations, inconsistency forces conservative settings and creates maintenance overhead. That is why more buyers will ask for tighter tolerance, better matching, and more transparent test standards.

Lifecycle Predictability Becomes a Procurement Metric

As fleet operations mature, buyers start modeling lifecycle cost. How many cycles before usable performance drops below mission requirements? How often do packs need balancing? How many packs fail early? In 2026, procurement language will increasingly shift toward “predictable lifespan” rather than “maximum advertised cycle life.” That pushes manufacturers to focus on process control and validation, not only materials.

Trend 4: “Custom Battery” Will Mean More Than Custom Voltage

Custom packs will remain important in 2026, but the definition of “custom” will change. Many OEM teams have learned that series count alone does not solve their real problems.

From Custom Voltage to Custom Load Profiles

A meaningful custom drone battery design starts with the load profile: peak current events, sustained current, mission duration, temperature window, and charging constraints. A pack can be “custom voltage” and still fail early if it is not built to match the true discharge pattern. Expect more OEM teams to specify current behavior and thermal boundaries as first-class requirements.

OEMs Will Demand Earlier Validation, Not Later Fixes

One of the biggest shifts for 2026 is timing. Instead of discovering battery problems after deployment, more OEM teams will bring battery design into early validation. That includes verifying voltage sag under realistic takeoff and payload transitions, confirming heat behavior in the final enclosure, and defining safe charging and storage routines that field crews can actually follow.

For teams sourcing around real mission loads, comparing industrial drone battery solutions can be a practical way to frame requirements and understand what “field-ready” pack engineering looks like.

Trend 5: New Battery Chemistries Will Be Evaluated More Cautiously

There will be continued interest in new chemistries and safety approaches, including semi-solid directions. But in 2026, adoption will be more cautious and use-case-driven.

Semi-Solid and Advanced Chemistries in 2026

New chemistry is not automatically better for UAVs. OEM teams will increasingly evaluate whether a chemistry improves safety behavior under their specific stressors: vibration, heat cycling, peak discharge events, and long-term storage patterns. For many industrial platforms, the most valuable improvements may come from pack engineering and validation rather than a chemistry switch.

The Key Question Will Change

Instead of asking “Is it newer?” more buyers will ask “What problem does it solve in my system?” If a chemistry improves stability but adds weight or reduces peak power, it may not fit performance-oriented drones. If it improves safety and consistency for fleets, it becomes interesting. In 2026, expect fewer blanket claims and more targeted adoption decisions.

What OEMs Should Prepare for in 2026

If you are planning platforms or supply contracts for 2026, the safest approach is to move from generic battery selection to system-aligned battery strategy.

Questions OEM Teams Should Ask Now

- Are we optimizing voltage architecture for real missions or for a simplified test case?

- Have we measured voltage sag and heat under peak and sustained load, in the final enclosure?

- Do we have consistency requirements and acceptance tests for batch-to-batch variation?

- Is the charging routine realistic for field operators, and does it protect lifespan?

- Are we defining “end of life” by mission usability rather than a generic capacity number?

Why Battery Strategy Becomes a Competitive Advantage

In 2026, reliability will be a visible differentiator. Platforms that deliver predictable flight time, stable power behavior, and safer operations will scale faster and win contracts more easily. A battery strategy that prioritizes system validation and consistency reduces operational friction and lowers lifecycle cost, which matters more as fleets mature.

Conclusion

The most important drone battery trends for 2026 are not hype cycles. They are shifts in decision-making. Voltage architecture will matter more than capacity labels. Battery failures will increasingly be traced to design debt and validation gaps. Consistency will become a procurement requirement, not a nice-to-have. And “custom” will mean matching real load profiles and lifecycle targets, not just changing series count. OEM teams that treat the battery as a system component—validated for real missions—will scale more smoothly and fail less.

Shengya Electronic: Engineering-First Support for 2026 UAV Battery Strategy

As a dedicated UAV battery manufacturer, Shengya Electronic supports industrial drone projects with an engineering-first approach focused on voltage architecture, safety margin, and lifecycle consistency. Shengya’s pack development emphasizes cell matching, process control, and validation aligned with real UAV load behavior, helping OEM teams define requirements that translate into dependable field performance. For a practical reference point, Shengya’s 6S high-voltage LiPo drone battery reflects the kind of voltage platform and pack engineering that many industrial UAV systems continue to rely on as operations scale into 2026.

FAQ

Q1: What are the biggest drone battery trends 2026 OEMs should watch?

A: Voltage architecture focus, lifecycle consistency, and earlier system-level validation.

Q2: Does higher voltage always improve drone endurance?

A: No. It can reduce current, but real gains depend on load profile, wiring losses, and thermal limits.

Q3: Why does a bigger Ah battery not always fly longer?

A: Voltage sag and cutoff limits can reduce usable energy under real UAV loads.

Q4: What should “custom drone battery” mean in 2026?

A: A pack matched to your discharge profile, temperature window, and lifespan targets—not just a different voltage.

Q5: How can OEM teams reduce battery failures in scaled fleets?

A: Validate peak load and heat in the final enclosure, and set clear consistency and acceptance tests.