The drone world is full of big promises right now. Every week, you see a new headline. They claim some battery breakthrough will double flight times and change how we move goods. But if you are an engineer or a buyer handling real hardware, things feel different. You buy a battery because the spec sheet looks amazing. Then, the aircraft comes down early. Why? The voltage dropped too fast under load.

There is a big gap between “lab data” and “flight data.” A Solid-state UAV battery might show great numbers on paper. But physics in the field is tough. The buzz around the solid state battery for drones is real. The tech is changing the game. But this only works if you know what to look for, beyond just the energy density number.

Most frustration comes from a simple mix-up. People don’t always know how new chemistry acts under high current. This article cuts through the noise. We will look at why some high-density batteries fail to deliver. We will also see how specific solid state li ion battery tech is finally fixing the gap between the promise of 30% longer flight times and actually getting them.

The Hidden Trap: Nominal vs. Usable Energy

It feels like a trick, even if no one meant it that way. You see a battery with high capacity and low weight. But the mission fails. Here is the typical “phantom capacity” problem that makes operators so mad:

- What the Paper Says:You buy a pack labeled 30,000mAh with high energy density.

- The Math:You do the numbers. You expect your flight time to jump from 45 minutes to an hour.

- What Actually Happens:In the air, the drone triggers a “Low Voltage” warning after just 50 minutes.

- The End Result:The battery still has 20% juice left. But the voltage is too low to keep the motors spinning safely.

This happens because energy density (Wh/kg) tells you how much fuel is in the tank. It doesn’t tell you how fast you can get that fuel out.

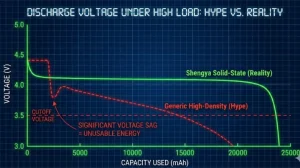

The Hidden Bottleneck: Interface Resistance & C-Rate

The main problem is usually internal resistance. In old-school lithium batteries, ions move through a liquid easily. Early versions of solid-state tech had a hard time with the connection between the solid parts. Think of it like running through water versus running through wet sand. This resistance causes a voltage drop (sag) the moment you pull high current.

For a solid state battery for drones, this matters most during two times: takeoff and hard turns. If the battery voltage sags when you push it, the flight controller sees a “dead” battery. This happens long before the energy is actually gone. You end up carrying dead weight. You paid for those amp-hours, but you can’t use them.

A great Battery discharge curve is flat and high. It stays above the cutoff point for most of the flight. This is where quality semi-solid tech stands out. It keeps internal resistance low. This lets the voltage hold up even when your motors need max power. This makes sure “usable energy” matches what is on the label. It fixes the phantom capacity issue.

How High Energy Density (340Wh/kg) Actually Translates to Flight Time

Weight kills flight time. Every gram you shave off the battery is a gram you can use for payload. Or, you just don’t carry it, which saves energy. This is why everyone wants that 340Wh/kg energy density number. It is a huge jump over standard LiPo batteries, which usually sit around 160-180Wh/kg.

However, losing weight is just step one. The chemistry has to be tough. It needs to handle the heat and stress of a mission without wearing out fast.

Case Study: Optimizing Heavy-Lift VTOLs

Let’s look at a real scenario. Take a VTOL (Vertical Take-Off and Landing) mapping drone. These machines eat up power when switching from vertical to horizontal flight. A standard LiPo pack is heavy. This limits how much ground you can cover. By switching to technologies utilizing the high energy density 340Wh/kg series, you get immediate wins:

- Lower Takeoff Weight:A 22,000mAh solid-state pack can weigh 30% less than a LiPo one.

- More Payload:You can use that weight savings to carry better sensors.

- Longer Range:Less drag and weight means you cover more acres per charge.

But here is the catch. If the voltage is low, the amps must go up to keep power (Watts = Volts x Amps). Higher amps mean more heat and less efficiency. This is why high voltage is often better. Putting in a 14S solid state battery pack (51.1V) lets the system run cooler than a standard 12S setup.

We saw a test recently. A surveyor swapped their standard power source for a High voltage drone battery from Shengya. The result wasn’t just a longer flight. The drone landed with cooler motors. The battery didn’t puff up. This proved the solid state li ion battery chemistry could handle the current spikes without that bad voltage sag. This specific 14S solid state battery pack (Model SY-14S 51.1V 26Ah) gave the stability needed to turn a math theory into a real flight log. You can view the specs for this industrial-grade high-voltage battery to see how high voltage and high density work together.

System Integration: Why the Pack Matters More Than the Cell

You can have the best cells in the world. But if the assembly is bad, the pack will fail. Thermal management, compression, and the Battery Management System (BMS) are the real heroes of long flights. Solid-state cells act differently than liquids when they get hot. They are usually more stable, but they still need precise assembly to keep the ion flow moving.

Buying raw cells and trying to solder a pack together in a garage is asking for trouble. Bad connections add resistance. That alone can kill the benefits of the fancy chemistry.

The Cost of Ownership Myth

People often think this tech costs too much. If you look at the price tag alone, a solid state li ion battery costs more than a generic LiPo. But let’s zoom out. Look at the Total Cost of Ownership (TCO):

- Cycle Life:Standard LiPos often get weak after 300 cycles. Good solid state battery packs are built for 800 to 1000 cycles.

- Buying Less Often:You buy fewer packs per year. This cuts down on shipping and downtime.

- Protecting Your Gear:A failed battery in a $50,000 LiDAR drone is an expensive mistake. Pro integration makes sure custom UAV battery packs stay stable, protecting your asset.

Shengya Electronics: The Manufacturer Behind the Tech

Shengya Electronic has quietly grown into a major player in high-end energy storage. They don’t just buy cells and wrap them up. Shengya makes the cells. They are deep into the science of it. Based in a huge 26,000-square-meter facility, the company has spent years perfecting the semi-solid and solid-state lithium chemistry that powers today’s toughest industrial UAVs.

Here is what they can do:

- Mass Production:They pump out 300,000 Ah daily. This means steady supply for big fleets.

- Extreme Density:They make cells ranging from 270Wh/kg up to a massive 340Wh/kg.

- Global Standards:Fully certified with ISO9001, ISO14001, and UL.

Shengya’s engineering team focuses hard on the problems we talked about here. They balance energy density with high discharge rates and safety. They don’t just sell batteries. They build the power source that keeps you in the air for that extra twenty minutes you need.

Conclusion

Moving to a solid state battery for drones isn’t magic. It is just science. The hype often skips over voltage retention and system integration. And you end up disappointed. But the reality is simple. When you pick a battery with both high energy density and a strong discharge curve, the gains are real.

Stop guessing based on the spec sheet. Look for the Battery discharge curve. Think about cycle life. Make sure the voltage fits your motor system. Getting real Drone flight time optimization means looking at the whole picture, not just weight.

FAQ

Q1: Will a solid-state battery work with my existing drone charger?

A: Generally, yes. Most solid-state Li-ion batteries use similar voltage ranges to standard Li-ion or LiPo batteries (like 4.2V or 4.4V per cell max). But, always double-check. Look at the charging voltage and current needs of the new pack. Some high-voltage types might need a charger that has LiHV settings.

Q2: Is the 30% flight time increase guaranteed for all drones?

A: No. It depends on your drone’s weight and power use. If your drone is already super light, saving battery weight might not change much. Heavy-lift drones, or long-range fixed-wing and VTOL types, usually see the biggest gains. This is because the battery is a huge part of their takeoff weight.

Q3: Do solid-state batteries perform better in cold weather?

A: Yes, this is a big plus. The stuff inside solid-state and semi-solid batteries doesn’t “freeze” or get slow like the liquid in standard LiPos. You will likely see less voltage sag on cold winter mornings. This makes them great for surveying in tough climates.

Q4: Can I use these batteries for racing drones?

A: You could, but it might not be the best choice. Racing drones need crazy bursts of power for just a few minutes. High-energy-density solid-state batteries are built for endurance—long, steady flights. They aren’t really made for the explosive 100C discharge rates used in FPV racing.

Q5: Why are 7S or 14S batteries becoming more common than 6S or 12S?

A: It comes down to efficiency. By bumping up the voltage (7S instead of 6S, or 14S instead of 12S), you can get the same power with less current (Amps). Less current means less heat in the wires and motors. This saves energy and helps the drone fly longer. It is a simple way to get more out of the system.