If you fly drones in the north, you know the story. It is January. The air is cold, around -10°C. You take off with a full battery. But just three minutes later, your flight controller yells “Critical Voltage.” The drone lands itself in an emergency. Yet, the screen says you still have 70% power left.

This is the cold weather effect on batteries. It is not just annoying; it is a full system failure. Many pilots think their battery capacity reduced a lot because of the cold. But that isn’t quite right. The energy is usually still inside the cells. It just cannot get out.

The issue isn’t simply “bad batteries.” It is a basic fight between the operating temperature of lithium ion battery chemistry and the high power needed for industrial work. To fix this, we must look past the voltage number. We should consider upgrading to low-temperature semi-solid architectures. These can get around those physical limits.

The Physics of the Freeze: Viscosity vs. Velocity

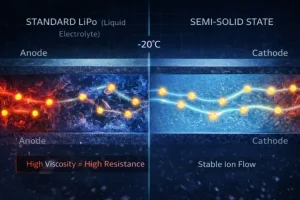

When lithium ion battery cold temperature performance drops, you are seeing a change in viscosity. Standard lithium batteries use a liquid to move ions between the positive and negative sides. As the air gets colder, this liquid gets thick and slow. Think of how honey gets hard when you put it in the fridge.

This physical change pushes up internal resistance ($R_{in}$). We know from Ohm’s Law ($V_{drop} = I \times R$) that voltage drop matches resistance.

- Summer: Resistance is low. Power flows easily. The voltage stays steady.

- Winter: Resistance jumps up because of cold-induced impedance. When you push the throttle (High Current), the voltage crashes instantly.

This is why lipo batteries in cold weather have a hard time. The fuel tank is full, but the fuel line is clogged. The ions just cannot move fast enough to give the motors the power they need.

System Architecture Failure: The “False Empty” Signal

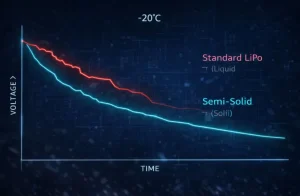

Look at the system architecture. Winter failure is often just a bad communication problem. The drone’s Health Management logic watches the voltage to guess how much flight time is left. It uses a set curve.

In freezing cold, high internal resistance makes the voltage sag way below that normal curve. The Battery Management System (BMS) sees this fake drop. It thinks you have low battery capacity. It sets off a false low-voltage alarm. Then, it starts a return-to-home flight or forces a landing to save the cell. It does this even if the battery is not actually empty.

This shows the system perception limits. Standard computer rules cannot tell the difference between an empty battery and a cold one with high resistance.

The Material Science Solution: Semi-Solid Electrolytes

Heating pads are popular, but they are just band-aids. They add weight and use up power. The real fix is changing how the electrolyte acts in the cold. That is why the industry is moving toward semi-solid electrolyte chemistry.

Old liquid electrolytes freeze and get thick. But semi-solid materials keep moving ions better in the cold. This tech lets batteries in freezing temperatures (down to -20°C or -40°C) keep a flatter power curve.

By using a semi-solid battery made for sub-zero work, pilots can keep the voltage above the danger line for the whole mission. The high discharge retention rate of these cells means the “usable capacity” in winter is almost the same as the “nominal capacity” in summer.

Case Study: High-Altitude Surveying in Sub-Zero Conditions

A survey team in the Alps had big problems. Missions kept stopping early. Their standard 6S LiPo packs hit the voltage cutoff only 12 minutes into a 30-minute map route. The cold air (-15°C) cooled the packs faster than the battery heat could warm them up.

The team swapped their power source for Shengya’s ruggedized industrial battery systems. These packs used the 330Wh/kg semi-solid technology. With the same payload weight and mission plan, they got about 92% of their normal flight time back. The voltage stayed stable. The flight controller did not trigger an early landing. This proved that the right chemistry is the best defense against the weather.

Conclusion

Winter does not mean you have to stop flying. The limit is in the liquid inside old systems, not the drone itself. If you understand the physics of cold-induced impedance, you can pick a power setup that works all year.

Don’t let the cold run your schedule. You can consult on cold-weather specifications to find a battery setup that fits your specific environment.

The Manufacturer Behind the Technology: Shengya Electronic

Shengya Electronic is a maker of high-end energy storage. They focus on industrial unmanned aerial vehicles. The company is different because they manage the whole production chain. They do everything from mixing cell materials to building the final battery packs. They are in a 26,000-square-meter facility. Shengya Electronic makes about 300,000 Ah every day.

The company’s main strength is making semi-solid and solid-state lithium tech. These products fix real problems for commercial flights: high energy density (up to 340Wh/kg) and long life (800-1000 cycles). With ISO9001, ISO14001, and UL papers, Shengya Electronic acts as a trusted OEM partner. They help clients who need safe power for mapping, watching, and carrying cargo.

FAQ

Q1: Is charging a cold battery dangerous?

A: Yes, very. Charging a cold battery (below 0°C/32°F) can quickly damage it. It causes “lithium plating,” where metal lithium builds up on the anode, which permanently reduces performance. It can also lead to shorts inside the battery. Always warm the battery to room temperature before charging it.

Q2: What is proper drone battery maintenance in winter?

A: Proper drone battery maintenance in winter involves keeping your battery packs warm before flying. Store them in a heated case or inside your car (around 20°C-25°C). Do not leave them out in the cold wind before takeoff.

Q3: What is the safe operating temperature of lithium-ion battery packs?

A: Standard LiPo batteries are usually rated to work between -10°C and 40°C. However, their performance drops quickly below 10°C. Shengya’s semi-solid series improves this range, allowing safe operation in temperatures as low as -20°C or even -40°C, depending on the model.

Q4: How does wind chill impact a lithium-ion battery in flight?

A: Wind chill is a hidden danger. Even if you warm your battery before flight, the fast-moving air during flight strips heat away quickly. A lithium-ion battery in freezing air can cool down below its working limit within minutes, causing a sudden voltage drop. For sub-zero conditions, we recommend using sticker insulation or fully enclosed battery covers to block the wind.

Q5: What specific battery precautions should I take during pre-flight checks?

A: In addition to keeping the battery warm, monitor its voltage when fully charged under a “test load.” Turn on the drone and spin the motors at idle on the ground for 30 seconds. If you see a sharp voltage drop right away, even with a full battery, it means the internal resistance is too high. These precautions can prevent your drone from failing mid-flight. Since cold weather can affect battery life unpredictably, always plan for 20-30% less flight time than usual, just to be safe.